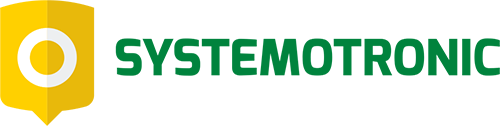

The process industry is undergoing a dynamic transformation. The demands for speed of response and safety are constantly increasing, and the era of Industry 4.0 requires the intelligent networking of all components.

Traditional pneumatic solutions are no longer sufficient to meet strict safety standards and modern operational requirements. ZANDER AACHEN provides the answer to these challenges: certified high-speed controllers and safety technologies that combine maximum reliability with easy integration.

Why New Solutions Are Essential Today:

- Increasing Complexity in thermal processing systems requires smarter, more adaptive control.

- Rising Demands for Speed & Safety push traditional systems to their limits.

- Industry 4.0 Integration calls for interconnected, intelligent technologies.

Our response: ZANDER high-speed controllers and certified safety technologies – delivering precision, performance, and protection for the future of industrial automation.

Our Highlights:

- Safety Relays, Shutdown Modules, Compact Controllers – including the versatile TALOS series

- Tamper-Proof Time Controllers – such as the robust SCB

- Certified Compliance – with EN 746-2, EN 61511, and EN 50156-1

Your advantage: Certified safety you can trust – clear, compliant, and uncompromising.

Rethinking safety – versatility without detours

Two contactors? Not necessary.

Our intelligent solutions meet standard-compliant diversity requirements—in a single device. No extra wiring. No added complexity.

With ZANDER AACHEN, you simplify your burner system architecture while enhancing operational safety.

ZANDER AACHEN is one of the few providers offering a certified solution for the safe monitoring of pressure, temperature, and flow sensors – up to SIL3 – with our SR3AD module.

This enables not just limit value monitoring, but the implementation of complete safety functions – standard-compliant, compact, and efficient.

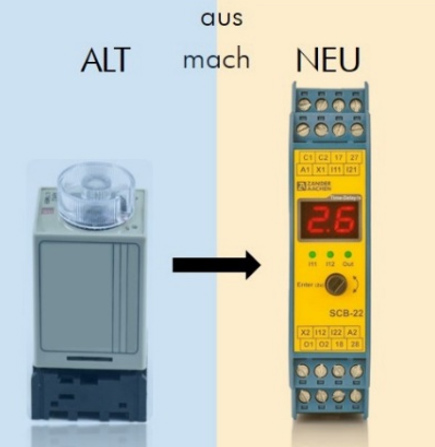

Retrofit Solutions for the Process Industry

Why replace at all?

Many existing systems still rely on pneumatic time relays – but these technologies are reaching their limits.

With ever-stricter safety requirements in line with EN 61508, EN 746-2 / 13577-2, and EN ISO 13849-1, pneumatic solutions often can no longer provide the necessary compliance or reliability.

Modern safety demands modern solutions.

Additional Technical Shortcomings of Pneumatic Time Relays:

- Leakages and Pressure Losses – reduce reliability and efficiency

- Delays from Wear and Tear – compromise timing accuracy over time

- No Condition Diagnosis or Remote Monitoring – limits transparency and proactive maintenance

Our SCB series electronic time controllers offer the perfect solution:

- ✓ Certified safety for industrial use

- ✓ Precise time control from 0.1 s to 99 h

- ✓ Tamper protection via PIN

- ✓ Easy-to-read LED display for status and diagnostics

Future-proof your system – with SCB time controllers from ZANDER.

And when more than just timing functions are required, our TALOS safety controller with 14 safe inputs and 3 safe outputs is the perfect addition to your system.

To reinforce, expand, and filter test pulses, we also offer a wide range of safety coupling relays – from one to seven safe contacts.

Comprehensive, well-designed safety from a single source – Zander Aachen.

Thank you for your interest in our functional safety solutions.

As the Safety Product Manager at Zander GmbH, I am happy to assist you in selecting and integrating safety relays, coupling relays, and compact safety controllers.